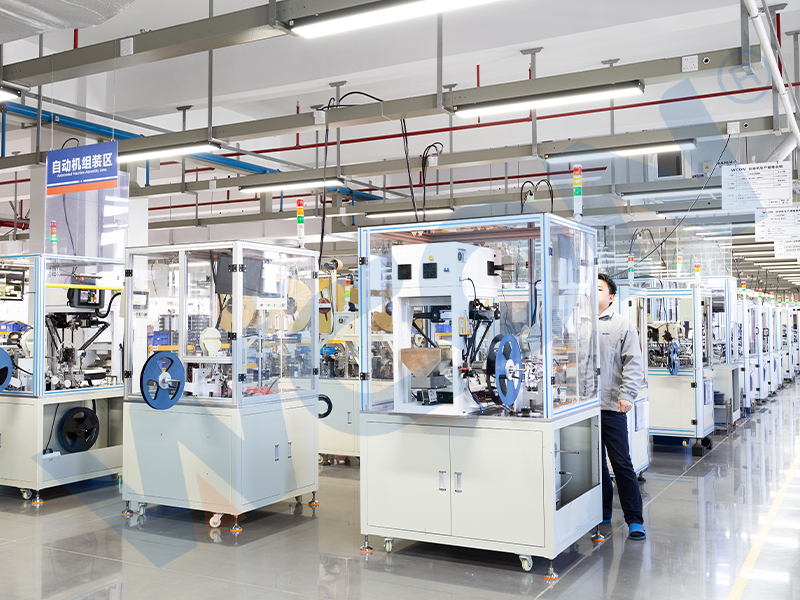

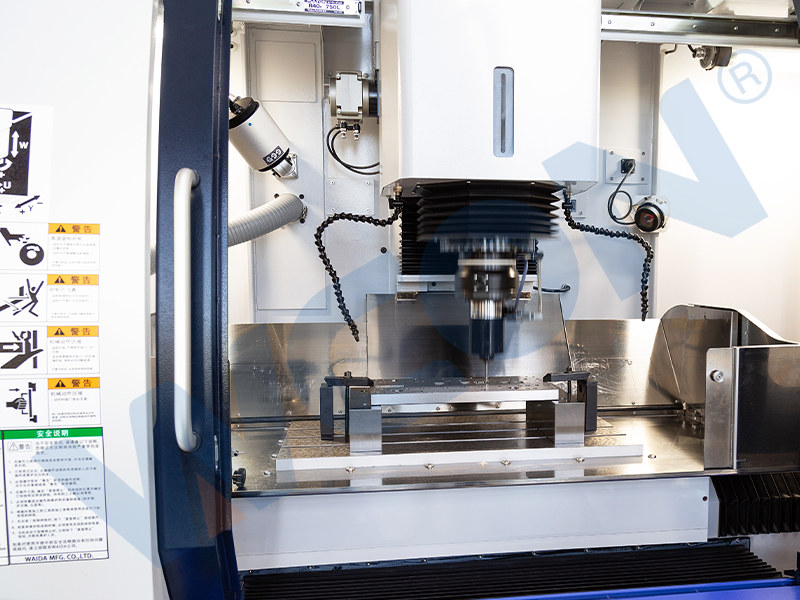

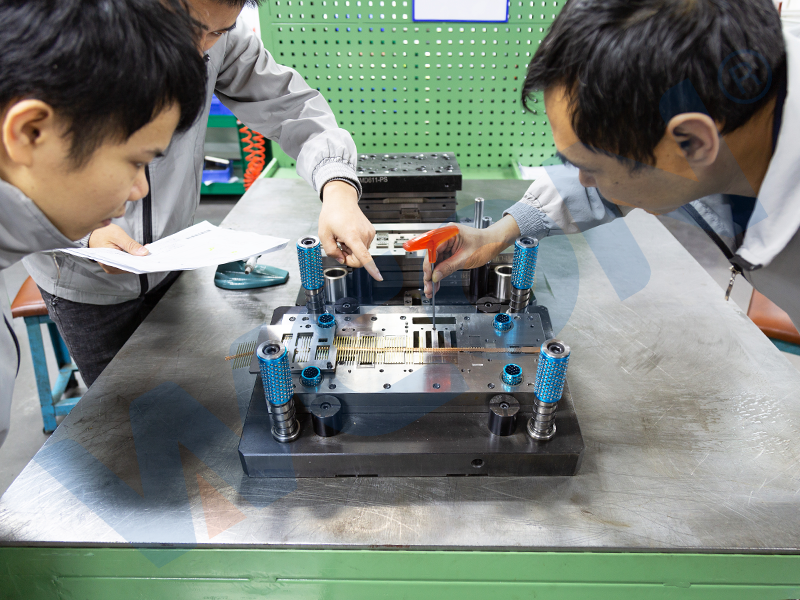

WCON, founded in Nov. of 2002, is committed to provide a high-end precision connectors and customized solution. Won specializes in the R&D, manufacturing and marketing of connector and cable assembly used in industrial automation and control, automobile electronics, new energy and Industrial cable assembly. The application industry of the products ranges from industrial automation and control, battery,motor and electric control system of new energy vehicles and photovoltaic inverter system.